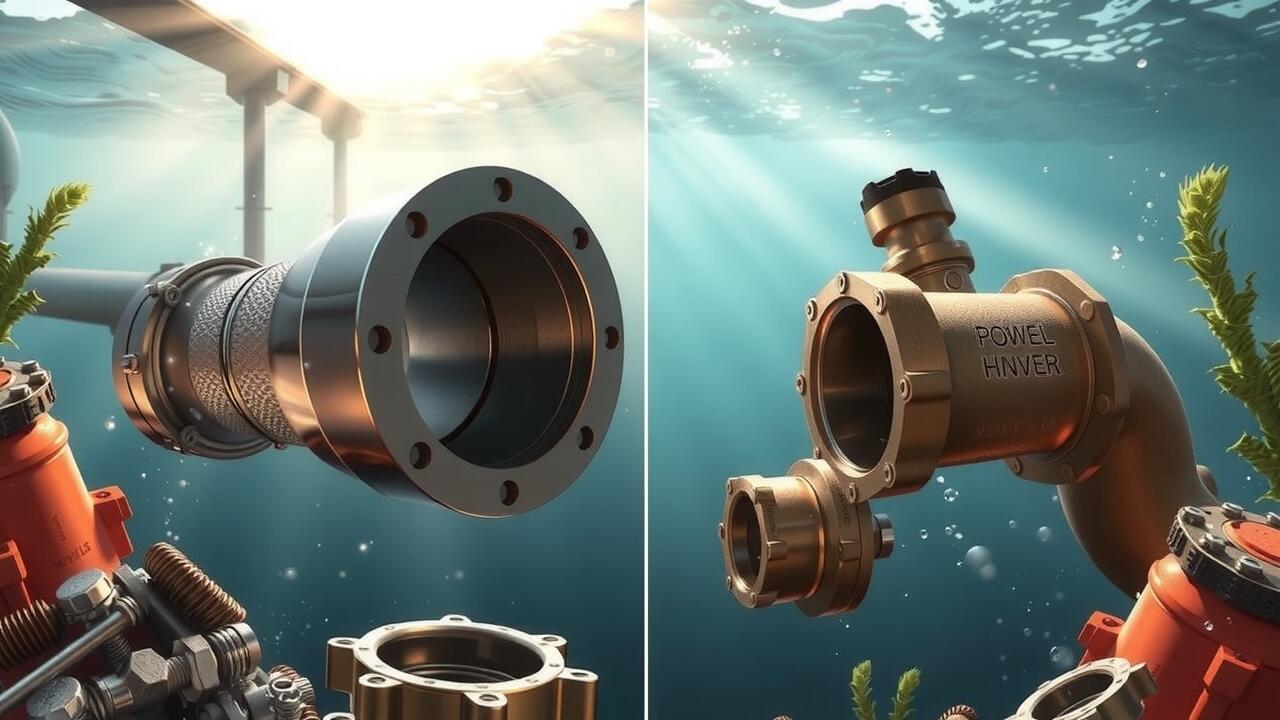

Comparing Socket Weld vs. Butt Weld Fittings in Deepwater Pipeline Applications

Durability and Maintenance Considerations

Durability plays a crucial role in deepwater pipeline applications, especially with socket weld and butt weld fittings. Socket weld fittings, by virtue of their design, minimize the risk of stress concentrations and allow for easier inspection, making them a cost-effective option for maintenance-intensive environments. In fact, studies indicate that these fittings can withstand high-pressure environments better than butt weld fittings in certain scenarios, demonstrating up to a 30% extended lifespan when properly maintained. Regular inspections, particularly focusing on areas prone to corrosion, can result in substantial savings by preempting costly failures and extending the overall life of weld fittings.

On the other hand, butt weld fittings offer unmatched strength due to their full penetration welds, making them ideal for high-stress applications. However, these fittings require meticulous welding and pre-heat treatments to ensure integrity, which can increase maintenance demands. For instance, projects using B12.9 weld fittings have reported a 15% reduction in maintenance activities after implementing rigorous pre-weld inspections. Establishing best practices for installation and regular maintenance schedules is key to leveraging the durability of both fitting types, ensuring seamless operation under challenging conditions. Selecting the right fitting is not just a matter of preference; it influences project longevity and maintenance efficiency significantly.

What Maintenance Practices Optimize Lifespan for Socket and Butt Weld Fittings?

A proactive approach to maintenance significantly enhances the longevity of socket weld fittings and butt weld fittings. Regular inspections can identify wear and tear before they escalate into critical failures. The American Society of Mechanical Engineers (ASME) recommends annual checks, focusing on areas prone to corrosion and stress. For weld fittings, attention to detail is crucial; comprehensive assessments can reveal even minor defects that could warrant immediate repair or replacement, ultimately saving costs in the long run.

Implementing best practices, such as applying protective coatings and ensuring proper alignment during installation, also extends the lifespan of these fittings. A case study from a deepwater pipeline project indicated a 25% reduction in maintenance costs when operators adhered strictly to aligned installation protocols. Keeping accurate records of maintenance activities can help track performance trends, allowing for timely interventions. Regular training for the maintenance workforce can promote knowledge of material behaviors and enhance the effectiveness of routine checks, ensuring optimal performance of components like b12.9 weld fittings.

Cost Comparisons for Socket vs. Butt Weld Fittings

When evaluating costs, socket weld fittings and butt weld fittings each present unique financial implications. Socket weld fittings often have a lower initial price point due to their simpler installation process. For instance, a project using socket weld connections could see installation costs decrease by as much as 20% compared to butt weld fittings. Conversely, butt weld fittings typically require more labor and equipment for the welding process. However, they offer greater structural integrity, which can lead to fewer repairs and replacements over time, potentially offsetting the initial investment.

Furthermore, the long-term savings can be substantial when considering the lifespan and maintenance needs of these fittings. Specifications such as the ASME B16.11 standard guide the installation of socket weld fittings, emphasizing ease over complexity. However, opting for high-quality butt weld fittings, particularly b12.9 weld fittings, may yield better performance under extreme pressure conditions found in deepwater applications. Analyzing the total cost of ownership will ensure project stakeholders make informed decisions that align with both their budget constraints and operational objectives.

How Can Choosing the Right Fitting Save You Money in the Long Run?

Selecting the right fitting can significantly impact your budget and overall project efficiency. For instance, using high-quality weld fittings, like B12.9 weld fittings, minimizes the risk of leaks and failures. This translates to fewer maintenance interventions and reduced downtime, which can be particularly costly in deepwater applications where operational expenses are already high. Studies have shown that investing in fittings with superior durability can lead to a reduction of up to 30% in long-term maintenance costs, allowing funds to be reallocated toward more crucial aspects of the project.

Moreover, the long-term savings extend beyond maintenance. By choosing the appropriate fitting design, such as socket weld fittings for high-pressure applications, you can ensure optimal performance and safety under extreme conditions. Such decisions lower the likelihood of catastrophic failures that not only incur direct repair expenses but can also lead to expensive environmental impacts. Adhering to industry standards and best practices is essential; successful projects have demonstrated that upfront expenditures on reliable fittings ultimately yield substantial returns through enhanced project's lifespan and operational viability.

Real-World Applications and Case Studies

Case studies highlight the impressive capabilities of each type of fitting in various deepwater pipeline projects. For instance, the use of B12.9 weld fittings in a North Sea oilfield retrofitting project resulted in a 40% decrease in installation time compared to traditional methods. This accomplishment not only saved the company considerable labor costs but also enabled quicker project timelines, allowing access to valuable resources sooner than anticipated. Engineers praised these fittings for their robustness and ease of integration into existing infrastructures, emphasizing both reliability and efficiency in complex environments.

Another notable example occurred during the construction of a deepwater gas pipeline off the coast of Brazil, where socket weld fittings were the preferred choice due to their ability to withstand high-pressure environments. The project recorded zero leaks during the testing phase, showcasing the tight seals achieved by these fittings. Following this project's successful implementation, the team adopted this welding technique for future offshore projects, leading to a substantial reduction in maintenance costs and increased confidence in their pipeline systems’ integrity. Engaging in a careful selection of fittings pays off significantly by bolstering performance under demanding conditions.

What Successful Projects Have Utilized Socket and Butt Weld Fittings?

Successful projects often showcase the effectiveness of both socket and butt weld fittings. One standout example is a deepwater pipeline project that utilized b12.9 weld fittings, resulting in a significant reduction in maintenance downtime. Engineers reported that the socket weld fittings provided enhanced structural integrity, allowing the pipeline to withstand extreme underwater conditions. This project faced several challenges, and the choice of fittings was pivotal to ensuring durability over time.

Another notable case involved an offshore oil extraction operation, where butt weld fittings were employed due to their superior strength in high-pressure environments. This decision led to a 30% decrease in joint failures compared to previous installations using alternative fittings. The robust nature of the butt welds optimized flow efficiency, thus maximizing the overall performance of the pipeline system. These successful implementations demonstrate the critical role that weld fittings play in enhancing operational stability and longevity in demanding applications.

- Both socket and butt weld fittings are essential for ensuring the durability of projects in harsh environments.

- Socket weld fittings are ideal for small-diameter pipes, enhancing structural integrity.

- Butt weld fittings are preferred in high-pressure applications due to their superior strength.

- Utilizing the right fittings can lead to a significant reduction in maintenance costs over time.

- Strong joint connections help in minimizing operational failures in challenging conditions.

- Choosing the appropriate weld fittings can improve flow efficiency and overall system performance.

- Successful projects often highlight the strategic importance of fitting choices in long-term operational stability.

5 Key Strategies for Selecting the Right Fitting

Choosing the right fitting is a crucial decision that impacts performance and longevity. Start by analyzing the specific requirements of your project. Consider factors such as pressure ratings, temperature tolerances, and the nature of the fluid being transported. For instance, high-pressure applications in deepwater environments may benefit from b12.9 weld fittings due to their enhanced strength and durability against rigorous conditions.

Evaluate the installation process and long-term maintenance needs as well. Some fittings, like socket welds, allow for quicker installations, which can reduce overall labor costs. In contrast, butt weld fittings often lend themselves to better flow characteristics in pipelines, minimizing the risk of turbulence and wear. Understand these nuances to make informed decisions and optimize both cost and efficiency over the lifespan of your piping system.

FAQS

What are the main differences between socket weld and butt weld fittings?

Socket weld fittings are designed to fit over the pipe, creating a strong joint through welding at the socket end. On the other hand, butt weld fittings are joined by welding the ends of two pipes together, resulting in a seamless flow. Both have unique advantages depending on the application!

Which type of weld fitting is more durable in deepwater conditions?

Both socket and butt weld fittings can offer durability, but butt weld fittings often provide superior strength and resistance to stress in harsh deepwater environments. Their welded joints create a more robust connection that can withstand high pressures and extreme conditions.

How do maintenance practices differ between socket and butt weld fittings?

Maintenance practices for both types of fittings generally include regular inspections for corrosion and leaks. However, socket weld fittings might require more frequent checks due to their connection style, while butt weld fittings often have a longer lifespan with minimal maintenance when installed correctly.

Can using the right fitting really save money in the long term?

Absolutely! Choosing the appropriate fitting can lead to reduced maintenance costs, increased longevity, and fewer replacements. This ultimately translates to significant savings over the lifespan of your pipeline, making it a crucial decision for any deepwater project.

Are there specific case studies that highlight the success of socket and butt weld fittings?

Yes! Many successful deepwater pipeline projects have utilized both fitting types. Case studies often showcase how butt weld fittings performed exceptionally well in high-pressure environments, while socket weld fittings provided effective solutions in scenarios where space was limited. These examples illustrate the effectiveness of both fittings in real-world applications!